Single or Dual-sided Card Printer: Which is Right for Me?

Many folks come to A Plus ID specifically looking for an ID card printer. They typically ask me whether a dual-sided ID badge printer is the right choice or if a single-sided printer is sufficient for their specific printing needs. That’s not an easy question to answer without first knowing a few things.

For example: if you’re designing your cards to feature an employee’s photo and your organization’s name and logo on one side, and you’re printing a total of between 50 -100 cards, a single-sided ID card printer will more than likely fit the bill.

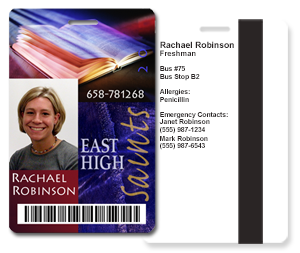

However, if you’re planning to feature employee and/or company information on the front and back of the card, we definitely recommend investing in a dual-sided (also referred to as a “duplex”) ID card printer.

Dual-sided printers are designed with a mechanism called a “flipper” which actually flips the card over inside the printer. This prints to both sides of your card simultaneously – in a single pass – which can equate to substantial savings when it comes to time. And time is money! This works especially well in large organizations that have a large or consistent volume of new hires by reducing the printing time.

If you work in an industry like healthcare, you know that it’s a mandatory requirement to have your ID card displayed properly on your person 100% of the time. With an ID card that’s printed on both sides, a healthcare worker’s information will always be visible.

When it comes to deciding whether a single-sided printer or a dual-sided printer will best accommodate your business requirements, there’s one very important thing you need to know. Using a single-sided card printer to do the job of a dual-sided printer is a cumbersome and costly idea.

There are several good reasons not to do this:

- The ID card template used for printing and populating the front of a card will be entirely separate from the template and the data for the back of the card.

- After printing the front side of your card, you will have to manually flip the card to print the back side. Essentially, this can double your production time.

- Manually flipping cards means that you’ll probably touch the card surface before it’s printed. Cards contaminated with harmful debris like oils from your fingers or airborne dust may cause the dyes to be improperly applied or, worse yet, cause expensive printhead damage.

- In most cases, you simply need to print one-color text on the back of a card. Using your standard color ribbon to print one-colored text is a tremendous waste of your colored inks.

- Lastly, customers must consider their budgets. Typically, single-sided printers are less expensive than the dual-sided printers. The single-sided option may be a good choice for a company with a lower budget.

At the end of the day, your company will need to consider the cost of the printer, time, and supply savings that can be achieved with a dual-sided printer.