Not all PVC ID Cards Are Created Equal

Here at A Plus ID we believe that the best way to empower our clients is through education about ID printers and the best practices when it comes to printing badges and PVC ID cards. After all, technology is just part of the equation – the other part is using the right supplies and methodologies to leverage your printer to its fullest potential. One aspect of this is choosing the right blank PVC ID cards. We cannot overstate this aspect enough: the right blank cards can significantly improve the quality of the final ID badge and extend the useful life of your printer. Let’s take a closer look at why choosing high quality PVC cards is so important.

PVC ID Card Surface

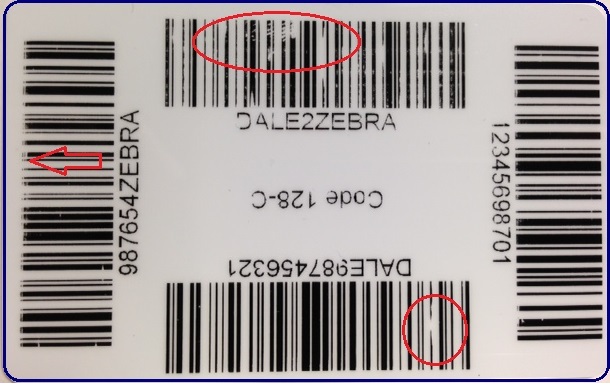

One of the problems with low quality PVC ID cards is an uneven card surface. Although the irregularities may seem tiny, they can cause big problems when they come into contact with the intricate technology of an ID card printer.

Remember, your printer only makes the process look easy. In reality, it’s a result of tens of thousands of hours of research, design and development. All of the components are designed to work together in a seamless manner. So even small irregularities like bumps or blemishes on a cheap PVC ID card can cause a lot of issues, such as:

- Bumps: If you’re using a direct-to-card ID printer, even small bumps can cause damage to the print head. Remember, with direct-to-card printers, the print head comes into direct contact with the surface of the card. Bumps can scratch the surface of the print head, and in some cases can even damage its internal mechanism.

- Blemishes: Cheap PVC ID cards can also have blemishes caused by a low quality manufacturing process. Unfortunately, in many cases these blemishes won’t just be covered up with ink pigment, especially with direct-to-card printers. This is because the surface of the card is integral to how the ribbon ink adheres to it. Thus, blemishes may still be visible after the printing because they’ll make the pigment look lighter or darker.

Both bumps and blemishes can significantly impact your daily operations. For example, saving just a few dollars with a pack of low quality ID cards can end up costing you hundreds of dollars in printer repairs.

Blemishes, on the other hand, can have a strong subconscious impact. For example, if you’re issuing temporary passes to your customers or patrons, blemishes can affect their perception of your brand and even how they perceive their experience with your company.

This is a very big deal, as numerous studies have shown that product packaging can have a strong impact on retail sales…Your ID badges or passes are part of your company’s “brand packaging” and therefore act as part of the customer experience with your company. If the “packaging” is lackluster, it will affect how your patrons perceive their experience.

PVC Card Sizing Issues

Another issue of concern with low quality PVC cards is the sizing of the cards. If the cards are not manufactured to the highest standards, the card dimensions may be a bit off, causing problems during printing.

For example, a size difference of just one millimeter can cause the card to jam or the ribbon to tear.

Further, those using retransfer printers may find that some of the images or text are cut off, because of incorrect card dimensions.

Get the Right PVC Cards

Here at A Plus ID we know just how important it is to use the right supplies in your ID printing process. That’s why we carry only high quality PVC cards from the best brands in the country. If you need help selecting the right cards for your printer, please give us a call at (866) 433-9737, or send us an email through the Contact Form.